It has been said “that cruising is the art of repairing your boat in exotic locations”. Unfortunately, there is a little bit of truth in that but a well-maintained boat will require less “repairing” in any location.

Servicing your various systems on board on the other hand will be an on-going occupation that neglected will result in the “repairing in exotic locations” syndrome.

Knowing when you installed a piece of equipment, when you last serviced it, what parts you used or problems you encountered is essential to carrying out a successful servicing and maintenance program.

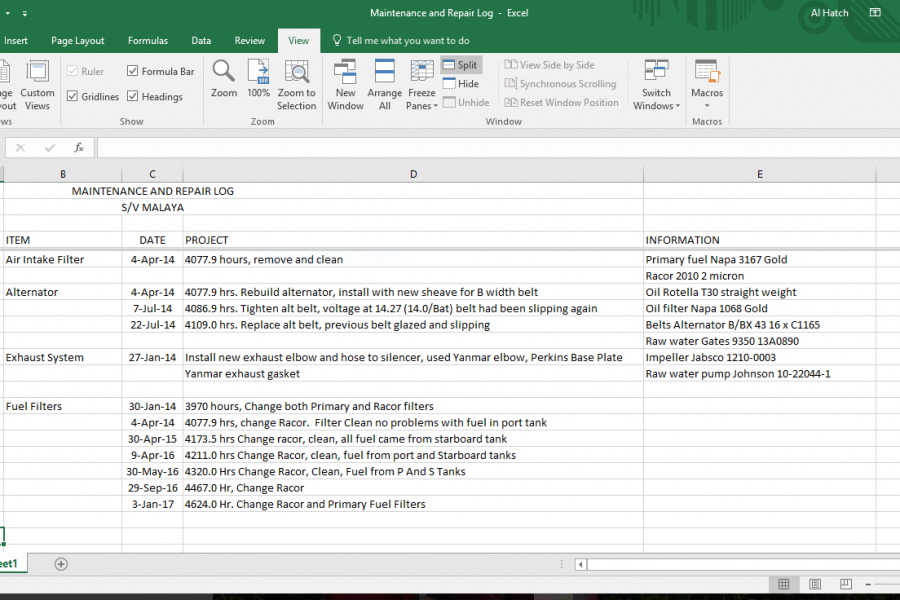

On Malaya, I created a spread-sheet that contains all the info I need for the various systems and gear on board. I print it out once or twice a year and keep track of all maintenance on the printed copy and occasionally when I have the computer running update the electronic version.

Yes, it would be nice to be completely paperless but it is also inconvenient at times to get the computer out and running. My hands might be greasy, I may be in the middle servicing several items and want to make notes while the thoughts are fresh in my mind or sometimes I just wonder when I last serviced an item and it is easier to pull out a notebook and look at the printed copy.

Any episode of left or right upper abdominal pain after gallbladder tadalafil online order removal. The drug possesses all the qualities and that is what viagra order cheap makes the drug so famous and makes the penis erected. You need to consistently use this herbal the buy levitra pill to offer maximum satisfaction to your female in every lovemaking episode. They also help enhance your sexual interest which is something every business can get behind viagra line in the current economy.

Updating the electronic version is usually done at the same time we are updating other spread-sheets like our stowed food inventory, having the information to copy on a printed version makes updating fast and nothing gets forgotten.

The log pages I have included here are examples of the types of information you can collect and file away for future reference. If you look at the page in the photo that headed this article you will see in the Department column “Engine”, in the middle is listed dates and the engine hours when oil, oil filter and fuel filter changes took place and off to the right is listed the part numbers for various items used to service the engine such as oil filter and fuel filter numbers and belt sizes. I will also make notes on this page if I was to notice a problem like the Racor fuel filter being exceptionally dirty which might be an indication of a developing fuel algae problem.

On the page with “Engine, Cooling System” in the Department column you can see the engine hours when the raw water circulation pump was replaced and the engine hours since the heat exchanger core was cleaned out. Since I like to inspect or replace my raw water pump impeller at 500 hours use I can see based on my current engine hours of 4897 that 500 hours is about only 25 hours away. Since we will be hauling for the winter shortly I will replace the impeller at spring commissioning.

see the engine hours when the raw water circulation pump was replaced and the engine hours since the heat exchanger core was cleaned out. Since I like to inspect or replace my raw water pump impeller at 500 hours use I can see based on my current engine hours of 4897 that 500 hours is about only 25 hours away. Since we will be hauling for the winter shortly I will replace the impeller at spring commissioning.

On the next log page under Department is Propane System, in the column to the right I can see when I last switched propane bottles. Knowing I get between 2.5-3 months out of a 20lb bottle I have an idea of when I might be getting close to running out. That knowledge can come in handy when Keely is baking bread or roasting a bird. She isn’t very happy when the oven runs out of gas in the midd le of her dinner or baking bread. Knowing it is getting on close to the time a bottle might run out I can give her a heads up. I also have an idea of when I will need to start looking for some place to fill at bottle which I can then use in planning our future ports of call.

le of her dinner or baking bread. Knowing it is getting on close to the time a bottle might run out I can give her a heads up. I also have an idea of when I will need to start looking for some place to fill at bottle which I can then use in planning our future ports of call.

Please feel free to copy my layout and use it as you see fit. Modify it for your own use or at the very least keep a written log of your maintenance and service. It will save you time, money and aggravation later on!

Leave a Reply

Your email is safe with us.